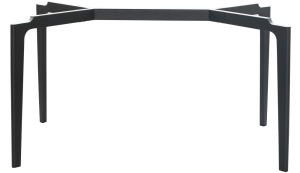

Tables come in many shapes, sizes and materials. Therefore, when you build or design a table, choosing the right legs is critical to the overall look and performance of the work. Next metal table leg manufacturers for you to sort out the following three common materials used to make table legs.

wood

Wood is probably the most common material used in table legs. Wooden legs bring natural elements to your decor, perfect for creating a warm and pleasant atmosphere. Whether you're covering the wood with paint or going for a more natural style, wood decor looks beautiful.

iron

In addition to its striking texture, cast iron provides reliable performance for your furniture. Having the strength and stability to support a table top is essential for good legs, and cast iron has both qualities. In addition, it counters the elements and ensures that the legs don't lose their visual appeal too quickly. So when you want a table with the perfect blend of aesthetics and durability, cast iron is a good choice.

aluminum

Another common material used for table legs is aluminum. Aluminum foil may be the first thing that comes to mind when you hear the word aluminum, but the metal has many uses. Aluminum legs are much lighter than cast iron legs.

How to repair a broken metal leg

Although welding is a common method of repairing metal damage, you can use cold welding compounds for a strong repair. This inexpensive material is easy to use, safe and durable. You can repair cracks in a variety of metals, such as iron, steel, copper and aluminum, in a matter of minutes. Like metal, cold welds can be painted to match the surrounding surface. The material is flexible for a short time, allowing you to shape it before eventually drying to a hard, steel-like consistency.Your repair will withstand high temperatures and withstand heavy use without the need for a conventional welder.

1. Extrude an equal amount of material from each of the two tubes contained in the package onto a clean work surface. Mix the parts together thoroughly using a disposable paint blender or wooden pin.

2. Thoroughly clean and dry the cracked area with a household cleaner. Remove any paint, primer or rust with coarse sandpaper.

3. Sand the surface to be welded with fine sandpaper.

4. Apply the weld along the crack length using a putty knife or wood pin. Fill the area completely and gently smooth the surface.

5. Remove excess material around the repair area with a rag.

6. Allow the cold welds to cure for 4 to 6 hours, then use fine sandpaper to smooth and even the surrounding area.

7. Use a clean cloth to wipe away any loose material.

8. Allow the cold-welded compound to dry completely overnight, then apply a coat of paint to mix the repair with the surrounding surface.

The above is the introduction of the common materials and repair process of metal table legs. If you want to know more information about metal table legs, please contact us.

Searches related to furniture legs sofa:

Post time: Feb-17-2022