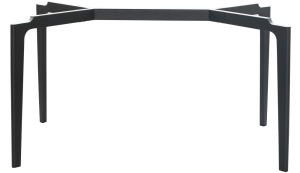

Amathebula eza ngamajamo amaningi, osayizi kanye nezinto zokwakha.Ngakho-ke, lapho wakha noma uklama itafula, ukukhetha imilenze efanele kubalulekile ekubukekeni okuphelele nokusebenza komsebenzi.Insimbi elandelayoumlenze wetafulaabakhiqizi ukuze uhlele izinto ezintathu ezilandelayo ezivamile ezisetshenziselwa ukwenza imilenze yetafula.

ukhuni

Izinkuni cishe yizinto ezivame kakhulu ezisetshenziswa emilenzeni yetafula.Imilenze yokhuni iletha izakhi zemvelo ekuhlobiseni kwakho, ezilungele ukudala isimo esifudumele nesimnandi.Noma ngabe uvala izinkuni ngopende noma ufuna isitayela semvelo, ukuhlobisa ngokhuni kubukeka kukuhle.

insimbi

Ngaphezu kokuthungwa kwayo okumangalisayo, i-cast iron inikeza ukusebenza okuthembekile kwefenisha yakho.Ukuba namandla nokuzinza ukusekela phezulu kwetafula kubalulekile emilenzeni emihle, futhi insimbi ekhonjiwe inezimfanelo zombili.Ngaphezu kwalokho, iphikisana nezakhi futhi iqinisekisa ukuthi imilenze ayilahlekelwa ukubonakala kwayo ngokushesha.Ngakho-ke uma ufuna itafula elinenhlanganisela ephelele yobuhle nokuqina, insimbi ekhonjiwe iyisinqumo esihle.

i-aluminium

Enye impahla evamile esetshenziselwa imilenze yetafula i-aluminium.Ucwecwe lwe-aluminium kungase kube into yokuqala efika engqondweni lapho uzwa igama elithi aluminium, kodwa insimbi inokusetshenziswa okuningi.Imilenze ye-aluminium ilula kakhulu kunemilenze yensimbi.

Indlela yokulungisa umlenze wensimbi ophukile

Nakuba i-welding iyindlela evamile yokulungisa umonakalo wensimbi, ungasebenzisa ama-cold welding compounds ukulungisa okuqinile.Le nto eshibhile kulula ukuyisebenzisa, iphephile futhi ihlala isikhathi eside.Ungakwazi ukulungisa imifantu ezinhlobonhlobo zezinsimbi, njengensimbi, insimbi, ithusi ne-aluminium, ngendaba yamaminithi.Njengensimbi, ama-weld abandayo angapendwa ukuze afane nendawo ezungezile.Izinto ezisetshenziswayo ziyavumelana nezimo isikhathi esifushane, okukuvumela ukuthi uzilolonge ngaphambi kokuthi zome zibe ukufana okuqinile, okufana nensimbi.Ukulungisa kwakho kuzomelana namazinga okushisa aphezulu futhi imelane nokusetshenziswa kanzima ngaphandle kwesidingo se-welder evamile.

1. Khipha inani elilinganayo lempahla kushubhu ngalinye kwamabili aqukethwe ephaketheni endaweni yokusebenza ehlanzekile.Hlanganisa izingxenye ngokucophelela usebenzisa i-blender yepende elahlwayo noma iphinikhodi yokhuni.

2. Hlanza kahle futhi womise indawo eqhekekile ngomshini wokuhlanza wasendlini.Susa noma yimuphi upende, i-primer noma ukugqwala nge-sandpaper emahhadla.

3. Faka isihlabathi ukuze ushiselwe nge-sandpaper ecolekile.

4. Faka i-weld eduze kobude be-crack usebenzisa ummese we-putty noma iphini lokhuni.Gcwalisa indawo ngokuphelele futhi ngobumnene ubushelelezi ubuso.

5. Susa izinto ezingaphezulu ezizungeze indawo yokulungisa nge-rag.

6. Vumela ama-welds abandayo ukuthi aphulukise amahora angu-4 kuya kwangu-6, bese usebenzisa i-sandpaper ecolile ukuze usheleleke ngisho nendawo ezungezile.

7. Sebenzisa indwangu ehlanzekile ukuze usule noma iyiphi impahla exegayo.

8. Vumela i-cold-welded compound ukuze yome ngokuphelele ubusuku bonke, bese usebenzisa ijazi lepende ukuze uhlanganise ukulungiswa nendawo ezungezile.

Okungenhla ukwethulwa kwezinto ezivamile kanye nenqubo yokulungisa imilenze yetafula lensimbi.Uma ufuna ukwazi ulwazi oluthe xaxa mayelana nemilenze yetafula lensimbi, sicela usithinte.

Ukusesha okuhlobene nosofa wemilenze yefenisha:

Isikhathi sokuthumela: Feb-17-2022